A little while back, I replaced the front struts on our 15 year old car. While I was doing that work, I noticed that several other parts in the wheel well were looking past their prime. It is recommended that you have your car aligned after replacing struts so in the interest of only having to do that once, I decided to replace some other parts that would also need an alignment.

The first item on the list was new inner and outer tie rods. Tie rods push and pull the wheels in and out, or in other words make the car turn left or right. They are also one of the parts that is adjusted during an alignment.

The red arrow points to the outer tie rod. The outer tie rod is the most common and easiest part to replace of the entire steering arm. The green arrow points to a lock nut. This nut is used to adjust how far or close the outer tie rod sits from the center of the car. Mechanics will adjust this nut as part of your alignment. The blue arrow points to the inner tie rod. Sometimes it is called a steering rod and it threads onto the rack and pinion. The purple arrow shows the dust boot that keeps the inner tie rods connection with the rack and pinion clean.

The red arrow points to the outer tie rod. The outer tie rod is the most common and easiest part to replace of the entire steering arm. The green arrow points to a lock nut. This nut is used to adjust how far or close the outer tie rod sits from the center of the car. Mechanics will adjust this nut as part of your alignment. The blue arrow points to the inner tie rod. Sometimes it is called a steering rod and it threads onto the rack and pinion. The purple arrow shows the dust boot that keeps the inner tie rods connection with the rack and pinion clean.

First things first, we’ll need to remove the outer tie rod. In my case, it was so rusted onto the inner tie rod and I already was planning on replacing the inner that I simply cut it off with an angle grinder.

Here you can see the old outer tie rod next to a new one. One of the main reasons that you would need to replace an outer tie rod is because the rubber boot protecting the ball bearing is cracked.

Once that is cracked, grit can get into the bearing and it will quickly wear out. I was able to find the exact same tie rod end for $7/pc on RockAuto.com.

Taking off the dust boot gives you access to the inner tie rod. I had to borrow a loaner tool from the auto parts store to remove the inner tie rod.

The inner tie rod has a ball joint where it hooks up to the rack and pinion. This ball joint should be firm, but the ones I removed could easily be moved around with my pinky finger.

Assembly is the reverse and fairly easy.

Moving right along, the next part that I wanted to replace on both sides was the lower ball bearings. Unfortunately, for this car, you have to replace the entire control arm with the bearings already pressed in. Here is a picture of the whole control arm.

and this is the lower ball bearing that connects the control arm to the steering knuckle.

and this is the lower ball bearing that connects the control arm to the steering knuckle.

Like the outer tie rod, once the protective rubber boot cracks and opens up, the bearing is doomed. These parts are so close to the wheel and road that they are subjected to a constant barrage of grit and grime.

In order to remove the control arm, you must also disconnect the stabilizer bar link (sometimes referred to as a sway bar).

The sway bar runs underneath your car and connects the left and right control arms together. When you’re speeding down the road and make a hard turn, this bar will transfer some of the suspension load from one side to the other. I found new links for $15/pc.

Removing the control arm was pretty difficult for me. There are 4 connection points to the car (including the sway bar link). The connection to the steering knuckle was the hardest because there is only room for a crescent wrench and the nuts were severely corroded.

The other difficult step was removing the 3 bolts that secure the rear bushing of the control arm. Red loctite was used on at least one of the bolts. Loctite is a special kind of glue used to hold bolts in place. It comes in two common varieties, red and blue. Blue can be removed with hand tools, but red has to be heated up to 550° F. My 300 ft lb impact wrench was no match for the red thread locker so I had to use a propane torch and heat it up (I only caught the lubricating/penetrating oil on fire twice).

After all of the blood, sweat, and smoke I finally ended up getting the old control arms out.

This was the part that I really wanted to replace.

Install is the reverse. Here is one of the new sway bar links installed.

The lower ball bearing looks much happier now.

Here you can see the tie rods, control arm, and sway bar linked installed.

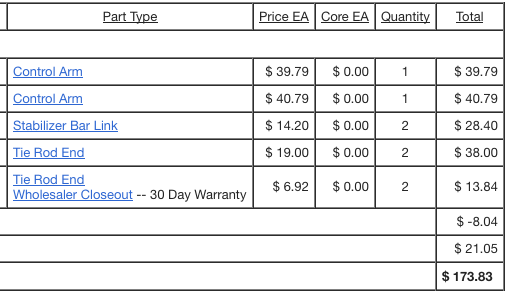

All of the parts set me back $174.

Labor was the biggest expense as it probably took around 8-10 hours. I also had to use some special tools including:

- Impact Wrench

- Propane Torch

- 27 mm socket

- 22 mm socket

- Inner Tie Rod Tool (free loaner tool from car parts store)

- 7/8 ” Crescent wrench

- PB Blaster (penetrating oil)

Would I do all of that work again? Probably not. It was a good learning experience, but we will most likely be selling this car within the next six months.

Playing with Fire – Frugal Living

[…] have replaced tie rods before on a different car, see here for that adventure. This time around, I wasn’t going to mess with the inner tie rods. I figured it was about […]